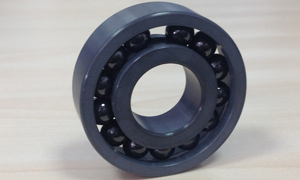

Ceramic ball bearings are one of the oldest types of bearings on the market. They are known for their strength and durability for holding up in stressed situations. Their great durability is what makes them popular for industrial applications. Most people do not think of ceramic as being a durable material for bearing purposes, but it actually holds up better than steel. The ceramic used in ball bearings is much tougher than regular ceramic. It is strengthened and stressed during the manufacturing process, to make it suitable. Ceramic can resist incredible levels of heat, but it does not conduct the same way that steel does. This makes it an ideal choice for situations that require a low cooling point to be maintained throughout the manufacturing process.

Why Choose Ceramic?

Ceramic ball bearings are used for many different purposes, including industrial purposes. Industries that require a high amount of spin in their equipment, such as with power drills, greatly benefit from this product. The high spin can often overheat a steel bearing, which causes it to conduct unnecessary heat. This can actually shave the steel if great care is not taken. Ceramic is a much better choice, because it does not conduct unnecessary heat like steel. It is often thought that ceramic causes more friction than that of steel, but this is not the case. Ceramic is lighter than steel, and it has a smoother texture. Ceramic bearings can move faster than most other types of bearings, and they cause less damage to the equipment they are used in. If they are put under too much pressure, they simply disintegrate, instead of causing damage to the machinery.

A Better Pricing Alternative

Ceramic ball bearings are in many ways better than steel. Most manufacturers prefer ceramic, and they use it on a regular basis. Ceramic bearings are not only more efficient, they are also cheaper to purchase on a large scale in bulk. Steel bearings are more common than that of ceramic, but ceramic is clearly the better option for those who need them for industrial applications. If you have never purchased bearings before, it may be a good idea to speak with a supplier representative. They will be able to guide you through the process of knowing which products are best suited for your intended use.